INFUGREEN 810 FOR INFUSE

NEW COUACH MOTOR YACHT

5 October 2021

Sicomin’s InfuGreen 810 bio-based epoxy infusion resin has been used for the infusion of the new Couach Fly 86/2600 Motor Yacht – one of the largest structures to be infused with bio-resins to date, and by far the largest yacht hull.

Sicomin’s InfuGreen 810 was used to vacuum infuse the 26-metre, 52 tonne superyacht’s hull, deck and superstructure producing a lighter, faster, more durable yacht, and reducing overall fuel consumption significantly.

Luxury goes green

As builders of both motor yachts for the leisure market and professional vessels for military, customs, and other government authorities, Couach (Bordeaux, France) is renowned for its very high engineering standards and quality of construction.

With a long history of building in composites, Couach has developed highly efficient vacuum infusion processes to build hull, deck, superstructure, and other components for their vessels. Whilst Couach traditionally used polyester resin systems, Sicomin – a key supplier of composite materials to the shipyard for more than 15 years – has worked with the Couach R&D team for the past four years on a test program to explore the benefits of epoxy resin systems, culminating in the successful implementation of Infugreen 810 and other GreenPoxy® bio-based epoxies in the latest Couach model.

With 38% of its carbon content from plant based sources, InfuGreen 810, is formulated to provide a more sustainable vacuum infusion resin with uncompromising performance. With the testing program complete, and the additional reassurance of the resin’s DNV GL type approval in hand, Couach prepared to infuse the 2600 Fly hull.

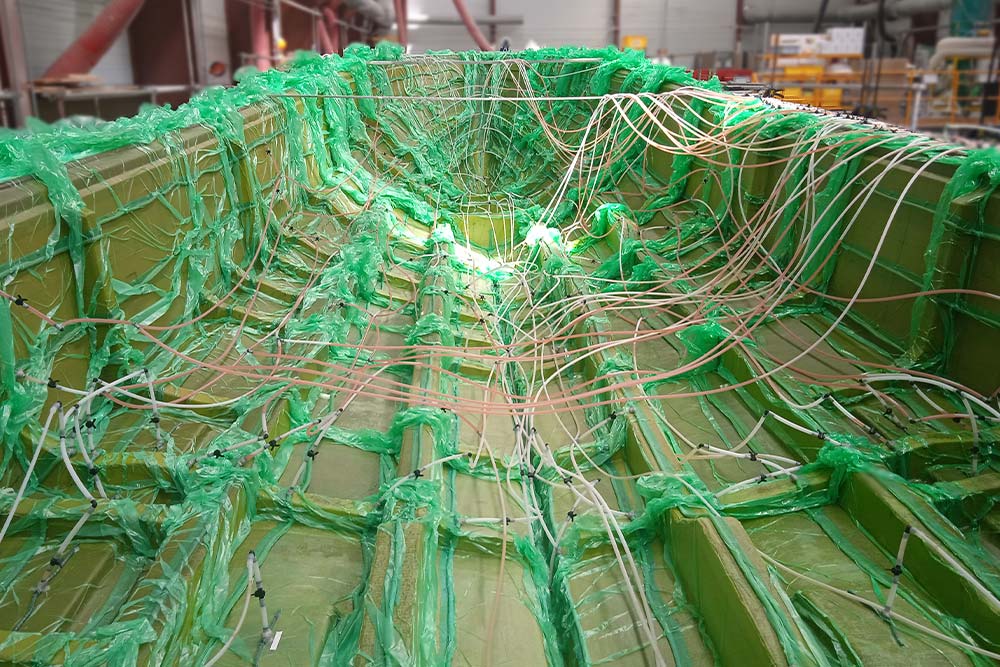

Sicomin also supplied release agents compatible with its epoxies and vacuum consumables that had been well proven in Couach production before this first major epoxy resin application. Then, the highly engineered E-glass laminate including sandwich core sections and a range of stitched multiaxial, woven, and unidirectional fabrics were assembled in the hull mould. For the final pre-production stage, Couach installed its in-house developed monitoring system to ensure the integrity of the vacuum and monitor the process conditions during the infusion itself.

Infusion of the first Fly 86/2600 hull was completed by Couach technicians with Sicomin’s technical team onsite to support the process and observe the infusion of the largest bio-epoxy hull to date. Both Couach and Sicomin noted the easy mixing, controllable hardener speed and excellent wet out resulting from the new process. Building on this initial success, InfuGreen 810 was then also used for deck and superstructure components with GreenPoxy 33 bio-based hand laminating resins used for secondary bonding in the yacht’s final assembly.

” Our InfuGreen 810 resin really does offer the optimum solution for infusion in a large structure such as the Fly 86/2600 ” comments Philippe Gruaud, Head of Technical Sales for Western France, Sicomin. “ The significantly lower viscosity and increased fibre wetting enable rapid, controllable and void free infusion of the laminate, particularly when using heavyweight multiaxial and woven reinforcement plies. It’s not just a more sustainable option, it’s the best technical option for a project like this. “

With the first of the new Fly 86/2600 series launched earlier this year, and now providing its owner with a sublime cruising experience, Couach currently has hull number two in production.

“With Sicomin’s InfuGreen 810 we have been able to build our Fly 86/2600 yacht in a more responsible and sustainable way, whilst also producing a lighter, stiffer, and more durable composite structure that reduces our impact on the environment. With superb processability, the added assurance of DNV GL type approval, and the technical support provided by the Sicomin team, our production team, as well as our customers, really appreciate this latest development. For sure, this is only the first of many yachts to be infused with InfuGreen 810 at Couach. ” Couach.